construction concrete batching plant users have more and more personalized requirements. Professional and high-tech stationary concrete batch plant is becoming more and more popular among users.Today's market, international cooperation pattern has been gradually formed. The main development directions for concrete batching plant are high speed, high precision, high reliability, intelligence, integration and open.

The core of the new generation concrete mixing plant development is open. The new generation of concrete batching plant adopts modular, hierarchical structure. At the same time, concrete batching plant offers unified application program joints to the outside.At present, open controlling system of concrete batching plant has normative architecture, communications, allocation. The operation platform and other functions of concrete mixing plant are the core of current study. The new generation of concrete batching plant will greatly meet the requirements of manufacturers to production line, manufacturing system, information integration, which is also the foundation of new manufacturing mode.

Today's market,The product competition is becoming increasingly fierce. Processing methods with high efficiency and high precision is greatly demanded.The biggest bright point of the new generation of concrete mixing station is intelligence which reflects: the intelligence to simplify programming and operation, intelligent operation interface, diagnosis and others, which makes the diagnosis and maintenance to the system. At the same time, the new generation of stationary concrete batch plany pays attention to the application and economic development. Flexible automation technology is the main means for manufacturing industry to adapt to the requirements of dynamic market and quickly update products. Flexible automation technology is the supporting technology for advanced manufacturing field and the main trend of concrete batching plant manufacturer field development.

2015年5月6日星期三

Chinese commercial concrete batching plant machine common problems

The overall technical content of Chinese concrete mixing plant is still relatively low compared with the foreign developed countries. At present, commercial concrete batch plant market in China is relatively chaotic and the technical level of commercial concrete batch plant manufacturers are largely varied. Several original domestic big machinery manufacturing company have been involved in the commercial concrete batch plant production and their starting point is relatively high, which will make the original competition more intense and increase several uncertainties. While the cement mixing station market war has just started and in the next few years there will be more than half of commercial concrete batch plant manufacturers be sifted out because of low profit and intense competition.

Commercial concrete batching plant in China has great regional differences and imbalance, such as commercial concrete in eastern areas is more advanced than that of western region,.From the overall situation,commercial concrete in coastal provinces is more developed than that of inland provinces. the popularity rate of commercial concrete is relatively low compaired with developed countries. Nowadays, the rapid development of construction and real estate in the concrete market will promote the development of commercial concrete in our country.

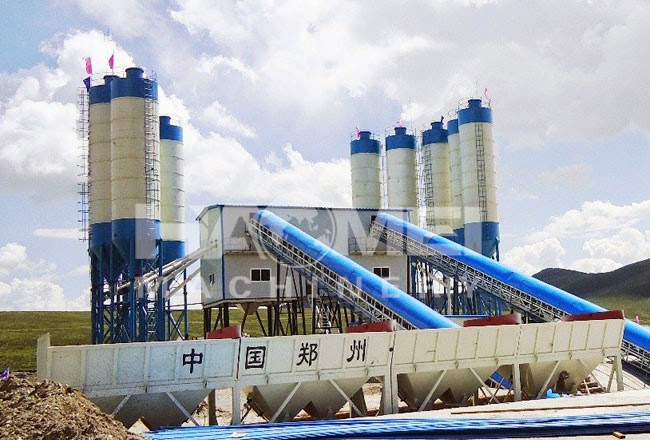

If you are in search of concrete batching plant supplier ,contact with us. Zhengzhou haomei machinery Co., Ltd has been in concrete machinery industry for 10 years. We can offer HZS concrete batching plant, mobile concrete batching plant and other products. About quality, each concrete mixer or concrete batching plant is strictly inspected by our members.To take advantage of our products and services, visit our website for more information.

Commercial concrete batching plant in China has great regional differences and imbalance, such as commercial concrete in eastern areas is more advanced than that of western region,.From the overall situation,commercial concrete in coastal provinces is more developed than that of inland provinces. the popularity rate of commercial concrete is relatively low compaired with developed countries. Nowadays, the rapid development of construction and real estate in the concrete market will promote the development of commercial concrete in our country.

If you are in search of concrete batching plant supplier ,contact with us. Zhengzhou haomei machinery Co., Ltd has been in concrete machinery industry for 10 years. We can offer HZS concrete batching plant, mobile concrete batching plant and other products. About quality, each concrete mixer or concrete batching plant is strictly inspected by our members.To take advantage of our products and services, visit our website for more information.

Factors Affecting Concrete Batching Plant Price

Concrete batching plant is an indispensable equipment in the construction industry.

There are strong market demands for concrete batching plant. When purchasing concrete batching plant, many people would encounter the same problem: What are factors affecting concrete batching plant price?This is also one of the most concerned issues for concrete batching plant buyers.

Firstly, the type of concrete batching plant would affect concrete batching plant price. There are many types of concrete batching plants in the current market. For different types of concrete batching plants, concrete batching plant prices are varied; Zhengzhou haomei Machinery Co., Ltd offers belt type concrete batching plant, skip type concrete batching plant and mobile concrete batching plant to you. Prices of these different concrete batching plants vary.

Secondly, concrete batching plant manufacturers are different. For concrete batching plant manufacturers, the technology and quality of concrete batching plant are not the same, so concrete batching plant prices vary from producer to producer. Generally speaking, concrete batching plant made by large manufacturers is more expensive than that made by small manufacturers. The reasons are that the craftsmanship, quality and many other aspects of concrete batching plants made by large concrete batching plant manufacturers have advantages than small concrete batching plant manufacturers. This is one of the main factors which makes concrete batching plant price varied.Zhengzhou haomei Machinery equipment Co., Ltd can send technicians to troubleshoot problem on location. We have received good reputation due to professional technique, attentive services, quality concrete batching plant and reasonable price.

There are strong market demands for concrete batching plant. When purchasing concrete batching plant, many people would encounter the same problem: What are factors affecting concrete batching plant price?This is also one of the most concerned issues for concrete batching plant buyers.

Firstly, the type of concrete batching plant would affect concrete batching plant price. There are many types of concrete batching plants in the current market. For different types of concrete batching plants, concrete batching plant prices are varied; Zhengzhou haomei Machinery Co., Ltd offers belt type concrete batching plant, skip type concrete batching plant and mobile concrete batching plant to you. Prices of these different concrete batching plants vary.

Secondly, concrete batching plant manufacturers are different. For concrete batching plant manufacturers, the technology and quality of concrete batching plant are not the same, so concrete batching plant prices vary from producer to producer. Generally speaking, concrete batching plant made by large manufacturers is more expensive than that made by small manufacturers. The reasons are that the craftsmanship, quality and many other aspects of concrete batching plants made by large concrete batching plant manufacturers have advantages than small concrete batching plant manufacturers. This is one of the main factors which makes concrete batching plant price varied.Zhengzhou haomei Machinery equipment Co., Ltd can send technicians to troubleshoot problem on location. We have received good reputation due to professional technique, attentive services, quality concrete batching plant and reasonable price.

modular concrete batching plant Advantages

modular concrete batching plant has uniform mixing. Mixtures going into the concrete mixet are homogeneous materials. Mixture in the concrete mixer, the mixing process includes blend and hydration. So the mixing time can be shortened.modular concrete batching plant has big concrete output and high efficiency. modular concrete batching plant is able to continuously and stably work.modular concrete batching plant has no leakage and small abrasion. The feed end of modular concrete batching plant is dry mixing and there are backpitches at two shaft ends. So there is no leakage problem. In addition, modular concrete batching plant has low faults and a long service life.Come to Zhengzhou haomei machinery co.,ltd for mini concrete batching plant and mobile concrete batching plant.

2015年4月19日星期日

HZS60 concrete batching plant ordered by Indonesia customer

In the November 2014, Indonesia clients came to Haomei to visit HZS series concrete batching plant. After a detailed discussion of the price, configuration, transportation and delivery, etc., the Indonesia client placed an order of HZS60 concrete batching plant and then signed a contract on the same day. The whole set HZS60 concrete batching plant was shipped on December 2, 2014 successfully.

HZS series concrete batch plant in Indonesia is the concrete mixing plant with vertical planetary concrete mixer which has good mixing quality and performance. At present, HZS concrete batching plant is more popular in the construction machinery market.

Welcome clients all around the world to visit Haomei’s factory and consult the production information from us, we will very happy to help you and offer the best service for you.

2015年2月15日星期日

Non-stop production of concrete in the Alps

A major challenge at the Obervermunt II of VIW – Vorarlberger Illwerke AG power plant project in Vorarlberg/Austria is the year-round just-in-time production of concrete at an altitude of 1700 m.

mobile concrete mixing batch plant type LINEMIX® made by SBM are an ideal choice for these challenging sites. Two LINEMIX® 3000 CM 410 H plants are used in parallel in the Silvretta region to assure trouble-free and continuous production of concrete until October 2017. This is carried out by a twin-shaft mixer with a quality concrete batching plant capacity of 130 m³ per hour depending on the required mixing time.

Trouble-free logistics

One of the key elements of the building activity is the underground hydroelectric power station. Transbeton GesmbH & Co.KG from Nüziders, has started mineral processing directly in front of the dam wall of Vermuntspeicher. The aggregates to produce concrete are processed from the excavated material on the site. Rock storage is carried out by a mobile high hopper with a storage capacity of 410 m³. To be able to assure a 24/7 operation throughout the year both the rock storage and the mixing plant are provided with a completely winterproof insulation.

Source: Haomei concrete batching plant cases

http://www.haomeibatchplant.com/projectcase/

2015年2月6日星期五

Central Pre-Mix strikes deal with Spokane Rock

Spokane Rock Products Inc. will lay off 42 workers as it sells its asphalt operations to Central Pre-Mix Concrete Co.

The deal between the two companies also calls for Spokane Rock to take over CPM’s concrete and aggregate business in the Tri-Cities.

Both Central Pre-Mix and Spokane Rock Products compete in the rock, concrete, asphalt, sand and gravel business for construction projects across the region.

Inland Asphalt – owned by the same parent company that operates Central Pre-Mix – will run Spokane Rock’s continuous asphalt mixing plant, which has been in operation since 2002 near Eighth Avenue and Havana Street.

In return, Spokane Rock Products takes over the 70-worker rock and concrete division Central Pre-Mix has operated in Pasco for years.

The deal includes a monetary payment, but Spokane Rock President Steve Robinson said he could not reveal the amount.

Inland Asphalt and Central Pre-Mix are part of Oldcastle Materials, the American arm of CRH plc, a multinational company based in Dublin. Oldcastle purchased Central Pre-Mix in 1997.

The 42 displaced asphalt workers have been asked to apply for jobs in the ready-mixed concrete mixing plant once it prepares to open this spring under the new owners, Robinson said. “Whether they’re hired depends on Inland,” he said.

Robinson said thin profit margins in the competitive asphalt sector prompted the company’s shift toward concrete and aggregate materials.

Spokane Rock Products was launched in 1999 after Acme Materials and Construction was taken over by Central Pre-Mix. That sale allowed for a new company to compete for a share in the materials market, Robinson said.

Spokane Rock Products will continue to have 132 workers in its concrete and aggregate rock operation. Most of them are drivers.

Robinson said the region’s construction industry still hasn’t recovered from the recession. “Most of our work is for government agencies, such as the cities (Spokane and Spokane Valley) and Spokane County.

“The county has greatly reduced the paving it’s doing,” in large part after completing the new sewer installations in Spokane Valley, he added.

“Basically, on the asphalt side of construction, it’s a very competitive market,” Robinson said.

Construction activity in the Tri-Cities is generally more robust than here, he said.

Spokane Rock Products has a concrete-aggregate operation there with about 50 workers. Spokane Rock will rehire the majority of the 70 or so Central Pre-Mix employees in Pasco, Robinson said.

Haomei machinery equipment CO., LTD.

Name: ANN MA

Office Add: No.14 Waihuan Road, New district, Zhengzhou, China

Tel: +86-371-65621392

Tel: +86-371-65621392

Fax:+86-371-86616825

订阅:

评论 (Atom)